Microvellum Toolbox Keygens

Alex Lopez – Accounting (541-423-1406, )Amy Reisnauer – USA Tech (919-271-6754, )Andrew Peel – Developer (541-423-1413, )Ben Woodruff – Reports Technician (541-423-1430, )Brent Morris – AU Tech (Complete Current Customer form for caller or give them his email )Charles Nolet – CA Tech Chris Endrikat – USA Sales (541) 423-1441, )Chris Leflamme – CA Sales/Support (438) 862-9388 )Clay Swayze – Marketing Director (541-423-1404, )Cory Sherman – Proj. The package at the Inn at the Commons averages $99 a night & includes:.Lodging for up to 2 occupants.Hot American Breakfast Buffet.1 Appetizer & Beer pairing at Common Block Brewing (includes two 10oz beers and a shareable plate, Chef's Choice).Drinks and Hors d'oeuvres at Welcome Reception on Wednesday, May 1, 2019.Wi-Fi.Complimentary Passes to Anytime Fitness.Airport transportation to and from Rogue Valley Airport. Based on the dates above I will send the hotel your rooming information and you can pay for your room upon check-in. That's great!

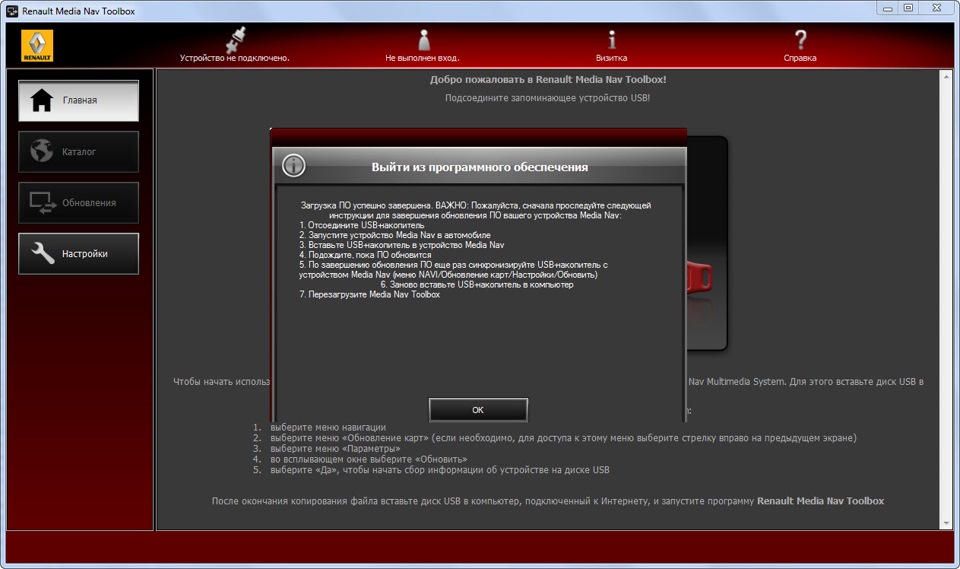

Toolbox AC Redist x86 by Microvellum.

You must be looking forward to experiencing the latest software.So, the way this works is i am going to collect a little information from you and I will send your request over to your account manager. I'll even be able to give you his contact information in just a bit.Once he receives this request, he will contact you and review our trial process with you. Typically, our trials are good for 30-days and you will have full access to our software with no restrictions. Ok, well thank you for your interest in our products. I'll be glad to help you with your trial request.So, the way this works is i am going to collect a little information from you and I will send your request over to your account manager. I'll even be able to give you his contact information in just a bit.Once he receives this request, he will contact you and review our trial process with you.

Typically, our trials are good for 30-days and you will have full access to our software with no restrictions.Your account manager will also see to it that your software is installed properly and that you have a basic understanding of how the software works. Company Name. Account Manager. Tim ScholmanAccount Executive & Account Manager905-769-4181. Chris LaFlammeAccount Manager(438) 862-9388. Scott HawksworthAccount Manager(043) 872-7364.

Account Executive. Isaac DailAccount Manager541-423-1417. Chris EndrikatAccount Executive541-664-1625 ex. 8541.

Ralph ButlerAccount Executive804-216-0381. Adam DirigAccount Executive607-988-4040.

Garen CevaAccount Executive514-677-5625. Michael JacobsMicrovellum Account Executive541-423-1425. Matthew ParisherMicrovellum Account Executive830-613-1133. Tim Scholman905-769-4181. Garin TrimbleAccount Manager(941) 815-7198. Matt Davies(048) 855-2626.

Tim Veale0800 206 904. Michael Jacobs541-423-1425. I was not able to contact him, would you like to leave a message for him? ( If Yes – Are you an existing Microvellum customer? ) (IF NO) Ok no problem, I can give you his contact information if you would like. Account Manager. Matt Parisher(830) 613-1133.

Isaac DailAccount Manager541-423-1417. Garin TrimbleAccount Manager(941) 815-7198. Chris LaFlammeAccount Manager(438) 862-9388. Martin LiemAccount Executive & Account Manager604-818-5436. Tim ScholmanAccount Executive & Account Manager905-769-4181. Chris LaFlammeAccount Manager(438) 862-9388.

Scott Hawksworth(043) 872-7364. Matt Davies(048) 855-2626. Tim Veale0800 206 904. Account Executive. Chris EndrikatAccount Executive541-664-1625 ex. 8541.

Ralph ButlerAccount Executive804-216-0381. Garen CevaAccount Executive514-677-5625. Michael JacobsHead of North American Sales541-423-1425. Martin LiemAccount Executive and Account Manager604-818-5436. Tim Scholman905-769-4181. I was not able to contact him, would you like to leave a message for him? ( If Yes – Are you an existing Microvellum customer?

) (IF NO) Ok no problem, I can give you his contact information if you would like. Account Manager.

Matt ParisherAccount Manager830-613-1133. Isaac DailAccount Manager541-423-1417. Garin TrimbleAccount Manager(941) 815-7198. Martin LiemAccount Executive & Account Manager604-818-5436. Tim ScholmanAccount Executive & Account Manager905-769-4181. Chris LaFlammeAccount Manager(438) 862-9388. Account Executive.

Chris EndrikatAccount Executive541-664-1625 ex. 8541. Ralph ButlerAccount Executive804-216-0381. Garen CevaAccount Executive514-677-5625.

Michael JacobsHead of North American Sales541-423-1425. Martin LiemAccount Executive and Account Manager604-818-5436. Tim ScholmanAccount Executive and Account Manager905-769-4181.

If you would like to speak to your personal Microvellum Representative, I can give you their name and contact information or even attempt to transfer you to them. Or, if you prefer i can just send them a notice stating you would like to be contacted. How would you like to proceed?. How many people are you wanting to get trained?. YES. To generate your request code, you will need to go to the splash screen for the product that you are trying to activate.There you will see a button labeled 'Enter Serial Number'.

Click that button and the activation screen will appear. In the authorization box you will see two options - 'activate via the internet' and 'Obtain authorization code by phone or email'. The first option does not require an activation code. The origins of totalitarianism schocken. The second option does.

Click the Obtain authorization code by phone or email radio button. Read me the request code.Once this is processed, you will open this window again and paste in the Authorization Code that you will be sent. Would you like me to pass along any additional comments to our activation's department?. Account Manager. Matt Parisher(830) 613-1133. Isaac DailAccount Manager541-423-1417. Eric McGillisAccount Manager715-781-0406.

Adam DirigAccount Manager607-643-2636. Garin TrimbleAccount Manager(941) 815-7198. Martin LiemAccount Executive & Account Manager604-818-5436. Tim ScholmanAccount Executive & Account Manager905-769-4181. Chris LaFlammeAccount Manager(438) 862-9388. Account Executive. Chris EndrikatAccount Executive541-664-1625 ex.

8541. Ralph ButlerAccount Executive804-216-0381. Garen CevaAccount Executive514-677-5625. Michael JacobsHead of North American Sales541-423-1425.

Martin LiemAccount Executive and Account Manager604-818-5436. Tim ScholmanAccount Executive and Account Manager905-769-4181. If you would like to speak to your personal Microvellum Representative, I can give you their name and contact information or even attempt to transfer you to them. Or, if you prefer i can just send them a notice stating you would like to be contacted. How would you like to proceed?. Have you been in contact with any of our reps concerning your renewal?

›Mar 12, 2014. Issuu is a digital publishing platform that makes it simple to publish magazines, catalogs, newspapers, books, and more online. Easily share your publications and get them in front of Issuu's millions of monthly readers.

Title: Joiners Magazine March 2014, Author: Magenta Publishing, Name: Joiners.You need to establish a maximum price that you are willing to pay. That will dictate what choices you have. I spent about $7800 for a Camaster Stinger 1 and I am extremely pleased with it. It was more expensive than what I wanted but I have no regrets - except that I didn't buy a bigger, more powerful Camaster. I have seen a lot of nice small projects that have been cut with a CNC Shark sold by Woodcraft.

Microvellum Toolbox Keygens Software

It is listed for $4000 but you have to buy a router to go with it. It would still be cheaper than my Stinger but it isn't even in the same league with respect to capability.I looked long and hard at building my own with a kit supplied by CNC Router Parts.

If you are good with mechanics, you can build one for less money than the Woodcraft and it will be a lot more capable.I talked to them several times and was very impressed. I talked to a couple of builders and they only had praise for the machine I was looking.

When I am in the market for a bigger machine, I will definitely give them another look. These are the only machines with which I am familiar enough to offer any opinion. Here are a couple of links. Whatever price point you choose you need to consider pricing for dust collection, workholding, endmills, CAD/CAM software (unless planning on using only free/opensource), &c. Another option is to consider a kit or DIY or opensource option.The Shapeoko was one of the first to encompass all three of those options.

It's since moved on to the Shapeoko 3, which is available as a kit from Carbide 3D (though the plans are available, and one could adapt it for self-sourcing) which is an amazingly capable machine w/ a default 16' x 16' cutting area for around $1,000.I got one and and XL upgrade for free as a thank you for volunteering on the forums) The Shapeoko 2 was a neat little machine and I've always regretted selling mine (ob. I got it for free for doing the initial version of the assembly instructions) - it has a 12' x 12' working area, and is quite capable - it has since been forked and is available from Inventables as the X-Carve - the changes are cosmetic mostly, or as in the case of the custom extrusion for the carriage, to simplify the kit / reduce parts count.

Still mystified that they haven't worked up a way to fasten the two X-axis rails together, or that they don't offer a 500mm (X) x 1000mm (Y) standard option. A recent development is the MillRightCNC, a small MDF machine (but the designer is planning an upgrade) - it's about as inexpensive as they can come. Anyway, you may find the Shapeoko wiki of interest - I'd like to think that everything one would need to know to select and run a hobbyist CNC router is there - if there's some question you're not finding an answer to let us know and we'll work it out. There's also a list of hobbyist CNC machines on a wiki page at the /r/hobbycnc subreddit on reddit.

Options for future expand-ability should be considerations IMO.Some of the small routers are now being offered with an optional rotary axis. With that and some clever programming you have a CNC lathe too.

Another option that's becoming popular are laser heads. Low power, mostly good for marking wood and other soft materials. They'll cut paper, but not much more.I notice the above options are not available for all the models Rockler and Woodcraft sell. The rotary axis needs a controller capable of 4 axis motion plus enough height under the cutter to mount it and be able to do reasonably sized work. The laser is much easier to add, it only needs ON/off capability in the control. I would find a used machine.I think it was James that has posted previously that many do not truly figure out what they need until they buy their second machine.

Having bought one not too long ago I am seeing that there is a lot of truth to that. Watch the Camheads or shopbot forum for a machine. It is fairly common for guys to upgrade from the desktop size to larger machines. If you are set on new, there is a detailed discussion by Gary Campbell about the first CNC purchase at the camheads site.It is very helpful regardless of the machine size one is looking for. I found deciding on a CNC was far more difficult than any of the other woodworking machines I have bought due to all of the electronics and moving parts.One other point to consider is support. I was lucky to find a lightly used Camaster machine, and one of the things that led me to buy it was the active Camheads forum, where I have found considerable help.

Shopbot also has a very active forum, as does the software vendor Vectric, which partners with both both Camaster and Shopbot. There are certainly many other capable manufacturers, but if like me you are a relative novice in the digital world, it is invaluable to be able to ask for help from folks who are using the same hard and soft systems. I'm sort of in the market for a small CNC router. But, I'm kind of spoiled since I have a number of CNC metal cutting machines.My current CNC's can cut wood although there are issues with wood, dust collection, spindles rpm and so on. This past Saturday I visited Woodcraft to look over their offerings.

The store manager told me I was lucky because their CNC 'expert' happened to be in.It's a pretty sad state of affairs if that guy is considered an expert. Anyway he couldn't tell me anything about the controllers of the Sharks, Axiom or General they represent, only that as a user I don't need to know that.

Then onto Rockler and just missed their CNC demo day.At least their guy admitted he knew nothing about the Shark controller. Tuesday I'll do some calling to the various manufacturer's tech supports trying to get straight answers. At this point I'm not optimistic.The small routers may be fine if all you want to do is work like Vectric software can handle, not so good if you want to go beyond that. Three of my customers are among the biggest musical instrument manufacturers in the country (we make small metal parts for them).

It's becoming obvious why they do all their wood cutting on CNC metal cutting type machine tools rather than routers (even though they could afford the best in routers). FWIW, Fender Guitars use Camaster Cobra twin head cnc routers. Fadal VMC's became the 'standard', at least for the west coast guys. Warmoth, Taylor and Tacoma Guitar all had Fadal's. Not so much that the Fadal's were the absolute best, more that Taylor started with them and others followed.A plus with Fadal's is they're basic, reliable machines and easy to repair. Warmoth has bought older Fadal's and had them rebuilt adding 10,000 rpm spindles. Attached is an example of the type work I like to do.

That's hand coded, 3 axis, about 40 lines of code using features of my Centroid controller.So far I don't think any of the low end controllers on the inexpensive routers are capable of this type cutting, out of plane arcs. The part was standing vertically when cut with a small wheel type cutter. I'm sort of in the market for a small CNC router. But, I'm kind of spoiled since I have a number of CNC metal cutting machines. My current CNC's can cut wood although there are issues with wood, dust collection, spindles rpm and so on.

This past Saturday I visited Woodcraft to look over their offerings. The store manager told me I was lucky because their CNC 'expert' happened to be in. It's a pretty sad state of affairs if that guy is considered an expert. Anyway he couldn't tell me anything about the controllers of the Sharks, Axiom or General they represent, only that as a user I don't need to know that.Then onto Rockler and just missed their CNC demo day. At least their guy admitted he knew nothing about the Shark controller. Tuesday I'll do some calling to the various manufacturer's tech supports trying to get straight answers. At this point I'm not optimistic.

The small routers may be fine if all you want to do is work like Vectric software can handle, not so good if you want to go beyond that. Three of my customers are among the biggest musical instrument manufacturers in the country (we make small metal parts for them). It's becoming obvious why they do all their wood cutting on CNC metal cutting type machine tools rather than routers (even though they could afford the best in routers).What do you need to do that Vectric Aspire can't handle Have you downloaded the demo and watched the videos. What do you need to do that Vectric Aspire can't handle Have you downloaded the demo and watched the videos Aspire may well handle the part programming.

I'm finding it's unlikely the low end router controllers have the ability to run programs coded the way we commonly do on my commercial CNC's. Things like cutting arcs outside G17, 18, 19 planes. This involves axis rotation.

Plus being able to do mathematical operations to generate the cutter paths on the fly, as in macro programming. My requirements are related to being able to make similar families of parts where a change of a couple program variables can alter the basic size and shape of a part all done while standing in front of the machine.For example, on a part we run often the program is loaded into the CNC controller, the operator uses the control's program editor to type in the diameter of a certain part feature. Not a chance I would be willing to pay 2,000 bucks for software that doesn't handle 4th axis code in an industry standard manner like Vcarve Pro and presumably Aspire.

Doug, I think you will have to put some of industrial milling preferences to the side if you are looking at what sounds like mostly low end CNC machines. If you want to work in wood, I think you need to keep in mind practical tolerances that take into account the fact wood expands/contracts with moisture.Gary has discussed this a few times on the camheads forum. Some of us consider 0.005' - 0.010' a reasonable tolerance for working in wood, but I know that would be considered terrible in the steel industry. If you increase your budget to the realm of $50k for a machine and $10k+ for software, then you can expect more. I am looking at Camworks and Mastercam to work with solidworks and those are both in the range of $5k for just 2.5 axis milling. I do not think guitars are the target market for most wood CNC manufacturers.To make a wood CNC router equivalent to a CNC for steel and cut 4x8 to 5x12 sheet goods at a production speed I would imagine it would weigh in the neighborhood of 20,000lb+.

I believe an Onsrud CNC that cuts these sheet goods at 1000ipm+ weighs more like 6,000 - 7,000lb. I'm about two steps ahead of you.I went through all the research and ended up buying a CNCRouterParts Standard 2448 kit.I just got it running about a week ago. For reference, I am a woodworker that also likes to make other 'stuff.' No real CNC experience other than using a CNC vertical mill to make cam masters over 20 years ago.I chose CNC Router Parts because it fit my needs, price, etc. And most of the lesser machines had lots of posts about issues. I did not find many posts about issues with their products.

In addition to the purchase price, somone already mentioned the 'after costs.' They add up quickly, so beware. Very happy with the machine so far. No serious issues.I have only made a few parts. The folks at CNCRP have responded faster than expected to my questions - both direct and on the forum at CNCZone.

It was quite a bit of labor to assemble, but not hard.Anyway, thought I'd chime in since I am a rookie. Oh, I plan on cutting mostly wood, but also Al, brass, etc.

Microvellum Installation

Now and then. Working on dust collection now.this thing kicks out some dust!